How to Become a professional CNC Machinist? Below are the knowledge you mast learn,

1. Surface treatment

Widely used surface treatment are anodizing, black oxide, chromium plating, nickel plating, titanium plating, zinc plating, electropolishing, passivation, PVD film plating, Teflon plating, Kanuc coating and so on.

2. Heat treatment

The commonly used heat treatment includes vacuum quenching, high-frequency surface hardening, modulation, nitriding, carburizing, salt-bath nitriding, etc.

3. Machining equipment

Turning machines, milling machines, CNC turning machines, CNC milling machines, vertical surface grinding machines with round tables, Cylindrical grinding machines, internal grinding machines, fast wire, slow wire cutting, machining center, electrical discharge machining, etc

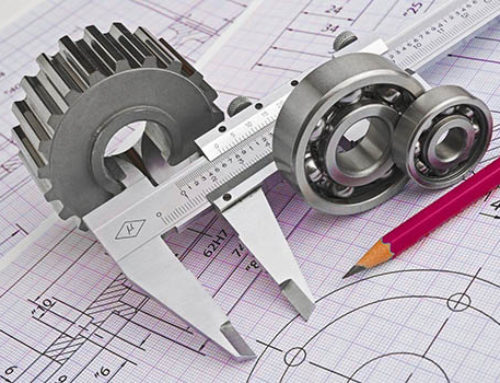

4. Inspection equipment

Heterometer, projector, hardness tester, micrometer, vernier caliper, plug gauge, thread gauge

5. Machining processing technology of precision parts

Determine the machine tool used in each process, clamping method, measurement method, processing allowance, cutting amount and time quota, etc., will be filled in the process specification table, that is, the mechanical processing process specification.

Parts’ machining process analysis of the is as below,

5.1 Check whether the drawings of parts are complete and correct, analyze the precision, surface integrity and technical requirements of the main surface of parts to reproduce some production equipment and production conditions can be realized.

5.2 Check whether the selection of parts and materials is appropriate and whether the process will become difficult and complex

5.3 Review the structure technology of parts and components, check whether the structure of parts and components can be economically and effectively processed.